Top Guidelines Of Insulated Spandrel Panel Detail

Table of ContentsThe 9-Second Trick For Spandrel Insulation9 Easy Facts About Spandrel Panel Window ShownLittle Known Questions About Nhbc Spandrel Panels.Some Of Architectural Panels7 Simple Techniques For Kawneer Spandrel Panel Metal Spandrel

These systems often include gaskets that are put in between the pressure bar and also mullions as well as feature as thermal breaks as well as assist with acoustic seclusion. These systems call for unique treatment in layout and building to ensure connection of the gaskets at horizontal and also vertical changes. Gaskets are likewise made use of to cushion the glass on the exterior and interior faces of the glass.There is normally a void in the gasket at the corners after shrinking occurs. With a properly created system the water that gets in the system at the gasket corners will certainly weep out through the snap cover weep openings. To reduce shrinkage of gaskets back from the corners using vulcanized edges as well as diagonally cut splices are recommended.

At the curtain wall border, keeping continuity of the air barrier minimizes air flows around the curtain wall surface. Combination of border flashings helps guarantee watertight efficiency of the drape wall and also its connection to surrounding wall components. Proper placement of insulation at the drape wall surface border reduces power loss and also prospective condensation concerns.

The spandrel area is commonly not heated, thus the interior setting does not warm the mullions and balance out the migration of the chilly temperature levels deep right into the wall surface. In the vision location the indoor heat helps to alleviate the cold as well as stops condensation. Consequently, do not shield in between the indoor section of mullions as well as surrounding wall surface building either.

Spandrel Panel Definition Fundamentals Explained

Back pans offer a second line of protection against water infiltration for areas of the curtain wall surface that are not visible from the inside and also are difficult to access. Water seepage in nontransparent areas can proceed for prolonged periods of time causing substantial damage prior to being discovered. Back frying pans likewise are to be chosen over aluminum foil vapor retarders in high performance and also humidified buildings as convection currents short-circuiting the insulation can cause condensation, moistening as well as eventually failing of these spandrel areas.

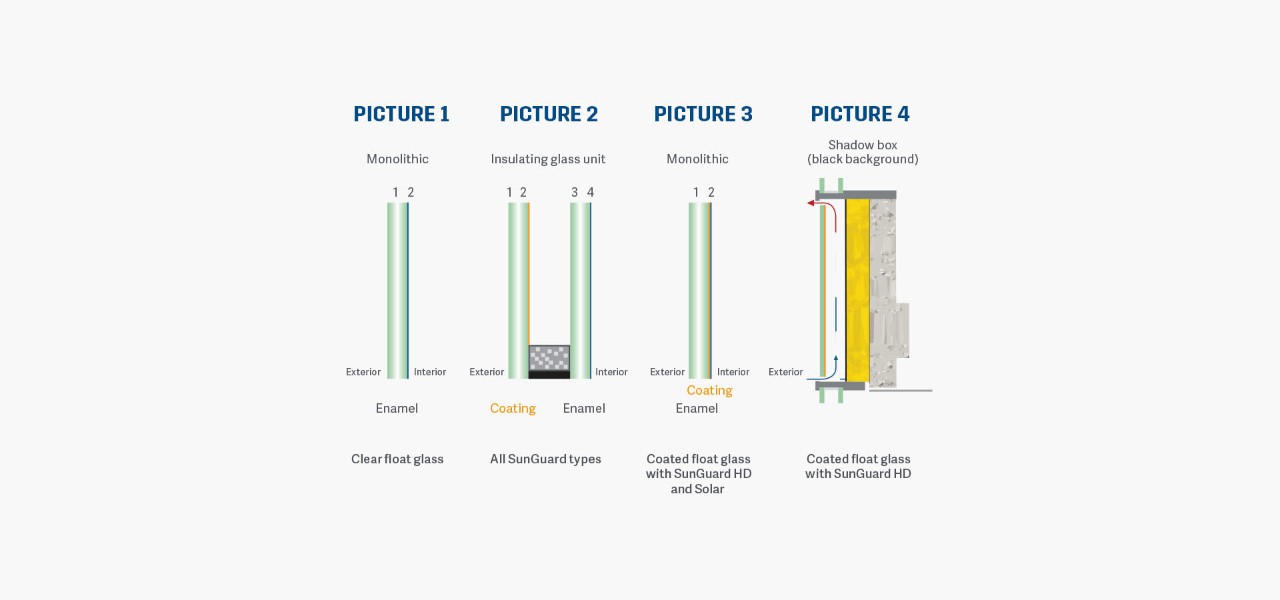

The metal sheet need to go to the very least two inches behind the glass and also may be painted or created to produce an appearance, yet reflective surfaces include one of the most visual depth to the wall surface. Insulation must also be mounted behind the shadow box if interior coatings avoid space air from contacting this area.

The links to secure the drape wall surface must be developed to allow differential motion while withstanding the lots used. In stick-framed light weight aluminum drape wall, upright mullions frequently run past two floors, with a consolidated gravity/lateral support at one floor as well as a lateral anchor only at the other. The splice between the vertical mullions will also be developed to enable vertical movement while providing lateral resistance.

Note that this movement slightly distorts the supports at the vertical mullions. Private systems of glass should fit the activity of the surrounding aluminum frame by moving along glazing gaskets, misshaping the gaskets or a combination of both. The motion of the glass within the structure and also the activity forced in the anchors tend to induce extra anxieties into a see this website stick framed system.

The 30-Second Trick For Kawneer Spandrel Panel Metal Spandrel

Laboratory-tested fire ranked assemblies might be needed in unsprinklered structures by some codes as Boundary Fire Control Solutions when the floor settings up are called for to be fire-resistance rated. The ratings of the Perimeter Fire Containment System have to be equivalent to or greater than the flooring rating. These systems provide self-confidence that the products used for boundary control stay in location for the specified period of the required score in a fire occasion.

Curtain walls and also boundary sealers call for upkeep to maximize the life span of the curtain walls. Border sealants, effectively developed and also installed, have a typical life span of 10 to 15 years although breaches are most likely from the first day. Elimination and also substitute of perimeter sealants requires careful surface area preparation and also proper outlining.

The very best strategy for sustainability of curtain walls is to utilize excellent design methods to make certain the toughness (optimum solution life) of the installment and also to use systems that have a good thermal break and high R-value (worths as high as R-7 are feasible with triple-glazed systems). Additionally, the usage of low-e and also spectrally selective glass layers can dramatically lower energy tons as well as enhance convenience close to the wall.

Curtain wall style must begin with the assumption that external glazing seals, perimeter sealant joints and drape wall surface sills will certainly leakage (insulated panels). The following sums up suggested define spandrel panel features: Select structures with wept glazing and pocket sills sloped to the outside to accumulate water that permeates the glazing as well as drainpipe it to the outside.

Not known Details About Spandrel Panel Window

Use as several 1/4-inch by 2-inch slots as needed for pressure-equalized systems. Design the water drainage system to deal with condensation along with rain. Curtain wall surface perimeters must have flashings (sill, jambs and head) that are secured to the air and also water barrier at nearby wall surfaces. Slope head as well as sill flashings to the outside to promote drain.

Glazing Methods and Their Effect On Efficiency Pressure Plate Glazing: In this system the glass as well as infill panels are mounted from the outside, typically versus dry gaskets. The external layer of gaskets is mounted and the gaskets are compressed versus the glass by the torque related to fasteners protecting a continual pressure plate.

The framework is dealt with and outside dry gaskets are mounted. Commonly just the top interior mullion has a removable stop. The glass system is moved right into a deep polishing pocket on one jamb far sufficient to permit getting rid of the contrary jamb as well as is after that relapsed right into the opposite glazing pocket and afterwards went down right into the sill glazing pocket.

Some Known Details About Spandrel Panel Definition

Often this technique is called "jerk" or "wiggle" glazing as a result of the manipulation required to get the glass into place. Efficiency is slightly decreased because completely dry steel to steel joints happen at the ends of the detachable stop at a point that should properly be air and watertight. Damp sealant heel beads will certainly boost efficiency as well as some systems include an extra gasket to create an air obstacle seal.

Architectural Silicone Glazing: In this system the glass or infill device is complied with the framework with a grain of silicone. External silicone climate seals glazing glass windows supplement the structural seal. Unitized systems are often structural silicone polished, particularly if four-side SSG is desired. Two-sided SSG, with stress plate glazing or wiggle glazing on the other two sides is appropriate to be area installed (storefront panels).

The CRF does not offer information concerning cold areas that could lead to local condensation. Projects for which condensation control is a vital problem, such as high indoor humidity buildings, call for project-specific limited component analysis thermal modeling utilizing software program such as THERM. Cautious evaluation and also modeling of interior conditions is needed to accurately approximate the interior temperature of the air at the within surfaces of the glass and also framework.